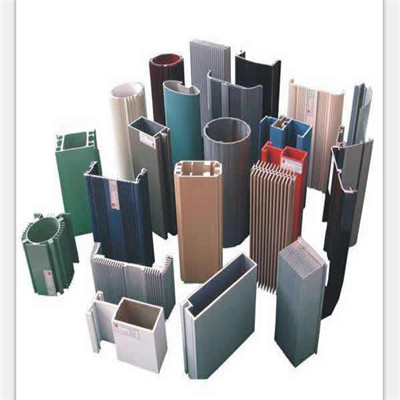

OEM customized fabrication Service special sizes Special/small qty is supported Fast delivery time

Advantages

Advantages

Products

Products

Service

Service

xiamen taohong technology co.,ltd

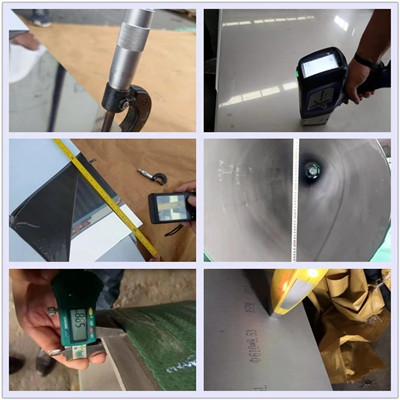

Xiamen Taohong Tech.co., Ltd achieve many certificates such as :ISO9001:2015, IATF16949:2016. We operates a quality management system approved to ISO9001:2008 and dimensional tolerances to EN755. European standard, American standard, high prime quality with short production time.

We have over 500worker,10000M workshop,expert to over 20 contries. Factory to airport:30 mins Factory to HSR:20 mins We have stable supply chain system in building materials for many years to ensure the material cost.

Xiamen taohong tech. co.,ltd have three indonstries supply system which operate with own factory in xiamen. steel, aluminum profile, hardware

If any product meet your demand, pls feel free to contact us. We can offer catalogue/ free samples to you.