Aluminum extrusion profile process

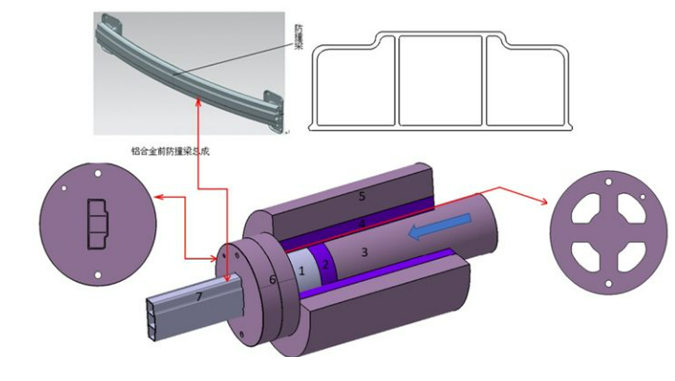

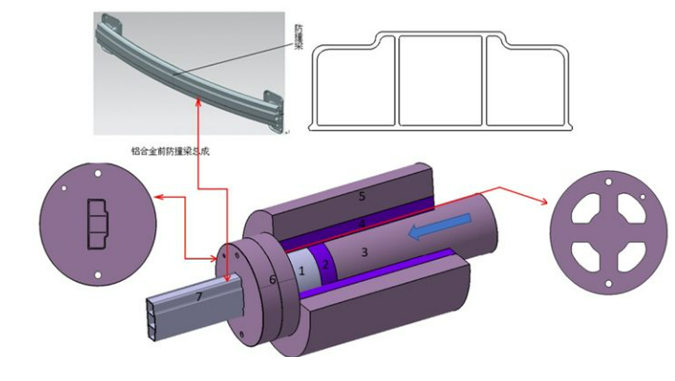

Aluminum extrusion molding (or aluminum extrusion molding) applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion barrel), forcing the aluminum billet to produce directional plastic deformation and squeeze it out from the die hole of th

e extrusion die. It is a plastic processing method to obtain parts or semi-finished products with required cross-sectional shape, size and certain mechanical properties.

Under the action of pressure, the aluminum ingot is divided into several metal flows, which enter the welding chamber through the shunt hole, are gathered in the welding chamber, are welded again under the environment of high temperature, high pressure, and high vacuum, and finally pass through the mold core and mold. The gap between the holes flows out to form a pipe or hollow profile that meets the size and performance requirements. If bending is required, a bending tool is added to the rear equipment.

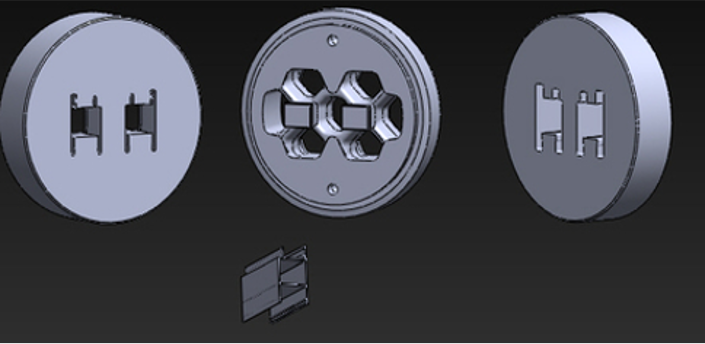

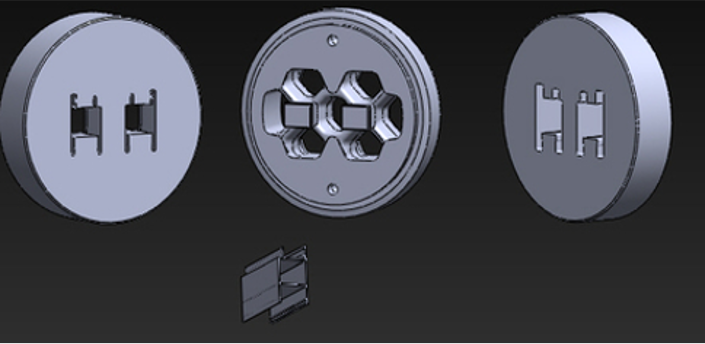

Aluminum extrusion die

An extrusion die is basically a thick, circular steel disc that contains one or more openings to create the desired profile. They are typically made from H-13 mold steel and are heat treated to withstand the pressure and heat of hot aluminum as it passes through the mold.

Heat buildup and pressure unevenness caused by aluminum extrusion design (such as thin walls, uneven wall thickness, and protruding features) are the biggest killers of extrusion die life.